BSM PACKING Flexible Graphite and Carbon Yarn Packing

Gaskets

Advanced construction for superior leakage control and high integrity. Layers of graphite tape are plied into compact strands. Each strand is reinforced with an Inconel* wire mesh covering. Strands are square plait braided to form a dense, but pliable packing. It is further enhanced with blocking agents. The packing’s exterior is then densely impregnated with lubricating agents to reduce stem friction and a corrosion inhibitor to prevent pitting.

Constructed with wire-reinforced braided yarn which surrounds a flexible and resilient asbestos-free core. The non-asbestos jacketed yarn construction encapsulates the wire reinforcement in the yarn, preventing stem wear and scoring. This special construction makes an economical, non-asbestos, general service valve stem packing for use in high-temperature and high-pressure applications.

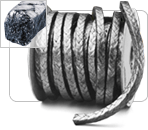

A unique reinforced braided graphite tape packing with a corrosion inhibitor, The carbon yarn reinforcement is provided within the graphite tape yarn, as well as the braided construction. 1400R forms a homogeneous mass under gland pressure, so that leakage cannot penetrate the packing set. The all carbon/graphite set withstands higher shaft speeds while limiting shaft friction.

Carbon fiber packing combines a new yarn formulation with superior blocking agents. New low modulus yarn provides the strength associated with continuous filament carbon fibers plus greater flexibility. This makes strong yet pliable, without the brittleness of conventional carbon packings. incorporates a high purity dispersion of inorganic platelets which prevent penetration of gases or liquids through the packing. Interbraid construction locks these blocking agents within the packing ring.

A pump and valve packing constructed from graphite tape which is twisted, braided and treated with corrosion inhibitors and a blocking agent. 1400 forms a homogenous mass under gland pressure for maximum sealability.

A tough yet pliable continuous filament carbon yarn packing which is impregnated throughout with PTFE to provide a non-contaminating, non-staining carbon yarn packing. was developed for the tough applications in the pulp and paper industry. It is specially designed to be used in High Pressure Feeders, Pre-Steaming Vessels and applications that are moving abrasive slurries. The combination of the carbon yarn and PTFE dispersions increases the chemical resistant properties when up against strong caustic and acid mediums.

It is also an excellent bottom anti-extrusion end ring in combination with 1400R in rotating equipment. This combination is ideal when attempting to reduce or eliminate flush water from a stuffing box. For more detail in this area go to the Water Management Section of this catalog.